Lubrizol Enhances Singapore Innovation Center

CLEVELAND - The Lubrizol Corp.'s Performance Coatings business announced new lab capabilities at its Innovation Center in Singapore.

The Innovation Center, a $5.5 million investment between Lubrizol's Performance Coatings and Personal and Home Care businesses, opened in October 2013 with the goal of extending Lubrizol's innovation and technical expertise to customers throughout Asia. Expanding from a small rented lab space to a significantly larger Lubrizol-owned facility, the Innovation Center allows for customer training events, product research and development, formulations development, in-depth applications testing, and a greater understanding of structural properties. Over the past several months, new coatings capabilities have come online at the center.

The addition of full extrusion capabilities for plastics allows for the testing of Solplus™ polymeric dispersants for pigment and filler dispersion into thermoplastic masterbatch and compounding applications. This complements the lab's additional capacity for dispersant testing in a wide range of thermosetting applications.

New automotive paint spray capabilities will enhance the development of customers' coatings by allowing Lubrizol to fully test a diverse range of both water-borne and solvent-borne formulations.

New formulation capabilities allow Lubrizol to better optimize coating formulas to help customers achieve desired coating characteristics through in-depth understanding of structures and prediction of performance.

Advanced equipment for measuring surface effects allows lab technicians to further research contact angles, surface tension, and haptic and adhesion properties of coatings on a variety of substrates.

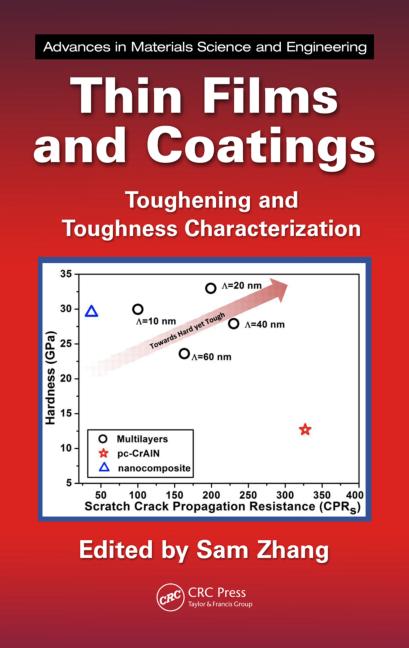

"Lubrizol's continued investment in the Singapore Innovation Center ensures we are focused on meeting the local needs of our Asian customers", said Hui Choo Tan, Performance Coatings regional technical manager. "We constantly strive to innovate the right solutions that help our customers bring differentiated coating performance to the most challenging of applications using locally-sourced raw materials and additives. In fact, the Innovation Center is already looking at how nano-technology can bring the next level of durability to coatings."

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!