Core-Shell Silicone Elastomer Particles

Tough but Flexible on Impact

We have all encountered very hard, highly crosslinked, mechanically strong coating systems that have a major disadvantage: Under impact, they are inflexible and brittle, resulting in deformations and spalling. The remaining unprotected substrate no longer satisfies optical aspects and other essential usage criteria, necessitating replacement or repair of the damaged object.

Improving Impact Strength

Incorporating flexible constituents in a highly crosslinked binder matrix results in markedly improved impact strength but a lower degree of crosslinking. This weakens the network density of the system as well as the surface hardness and chemical resistance. Combination with a second microphase, such as dispersed rubber or thermoplastics, can lead to significantly improved toughness. In this type of in-situ generation of particles, however, it is extremely difficult to control the particle size without fundamentally altering the properties of the polymer matrix.1

It is desirable to incorporate some ductile segments in the highly crosslinked, brittle matrix without impairing the network or mechanical properties, i.e. to generate tough, resilient but hard coatings.2

Using silicone core-shell rubber technology, it is possible to combine these originally contradictory properties. This article describes the use of ALBIDUR® core-shell silicone elastomer technology in a two-pack epoxy resin system and its influence on the mechanical properties of the coating generated.

The Technology

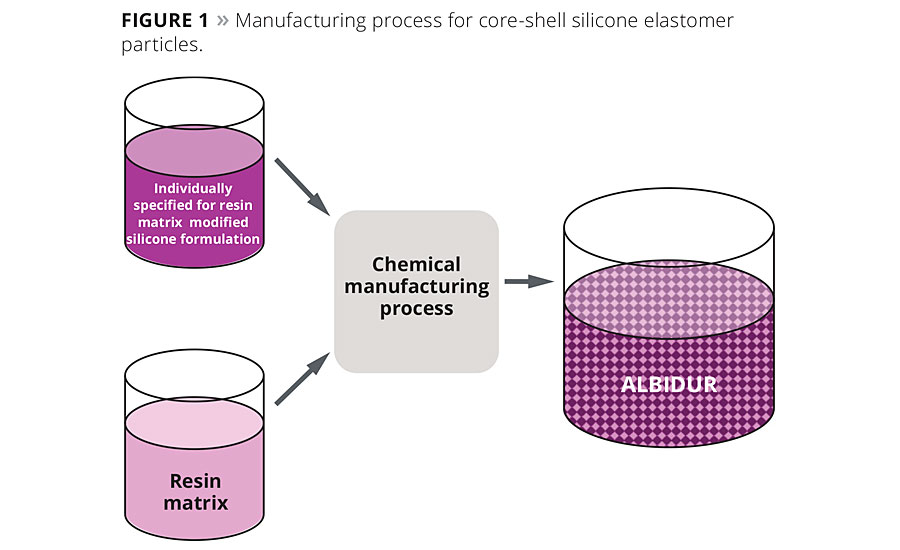

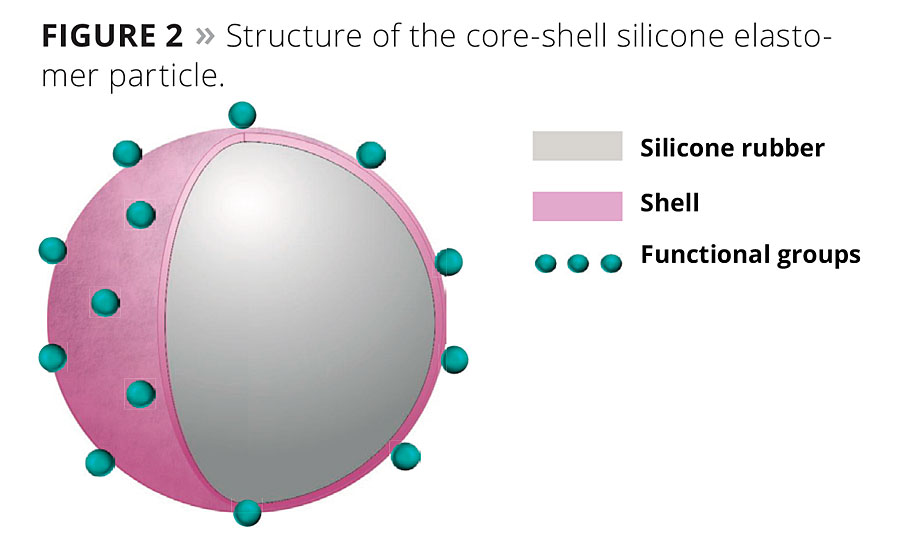

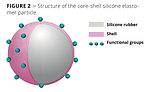

ALBIDUR technology involves the use of a patented process to permanently incorporate in-situ small silicone elastomer particles in a resin carrier (Figure 1).3 The special feature is the two-phase nature of the core-shell particle. The center is a silicone rubber core that promotes the tough, resilient characteristics, encased by a shell. No covalent linkage exists between the core and the shell; the shell is simply physically anchored to the core. As a result, there is hardly any change in the glass transition temperature in the cured paint film. The shell is adapted to the chosen binder matrix and, additionally, possesses suitable functional groups to link to the binder matrix of the coating (Figure 2).4

Because of the choice of shell and the related stabilization, there is no tendency for settling or phase separation of the particles. This behavior is retained during curing so that a statistical distribution of all core-shell particles exists during both the uncured and fully cured stages (Figure 3). Due to the statistical distribution within the binder matrix, the elastomer particles ensure a uniform impact strength. The external forces are largely absorbed during this process by the elastomer particles, like a shock absorber, and thus ward off fracturing in the coating.5

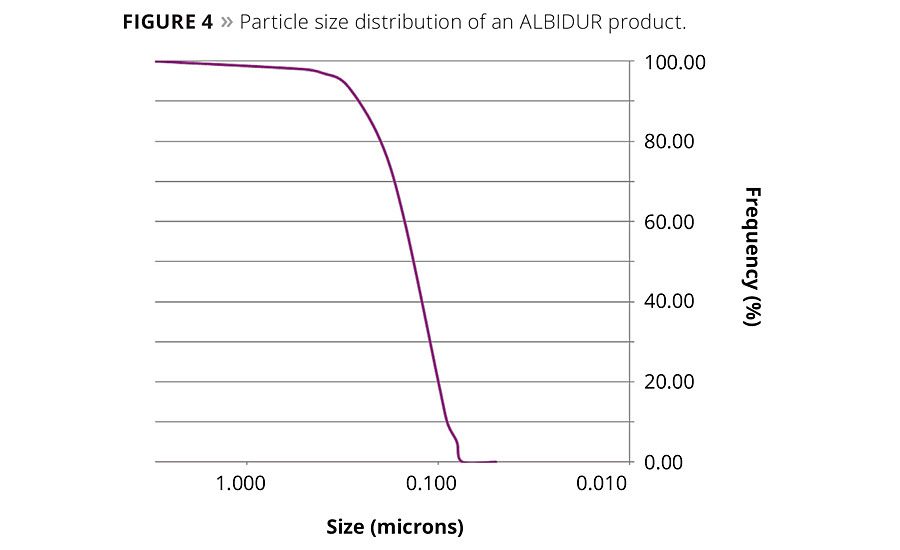

The manufacturing process yields particle sizes between 0.1 and approximately 3 µm, with over 90% of the particles smaller than or equal to 0.3 µm in size (Figure 4). The particle sizes and the differing refractive indices of the silicone elastomers and the surrounding resin matrix impart the white color of the silicone elastomer core-shell particle dispersion (Figure 5).

Because this is a patented platform technology, it is possible to upgrade various resin systems, such as polyols, acrylates or epoxies, to become ALBIDUR, based on the use of customized silicone elastomer formulations. The products are solvent-free and can be stored for 12 months at room temperature.6

Test Methods

The following application-related tests from the industrial paint sector were used to evaluate the influence of silicone elastomer particles on the impact strength:

- Falling Weight Impact Test (DIN EN ISO 6272-1);

- Multi Impact Stone Chip Test (DIN EN ISO 20567-1).

The specimens were also subjected to further tests such as the Constant Climate Condensation Water Test (DIN EN ISO 6270) and Salt Spray Test (DIN EN ISO 9227 NSS). The pencil and Erichsen pencil hardness were also determined along with the sliding resistance of the coating surfaces.

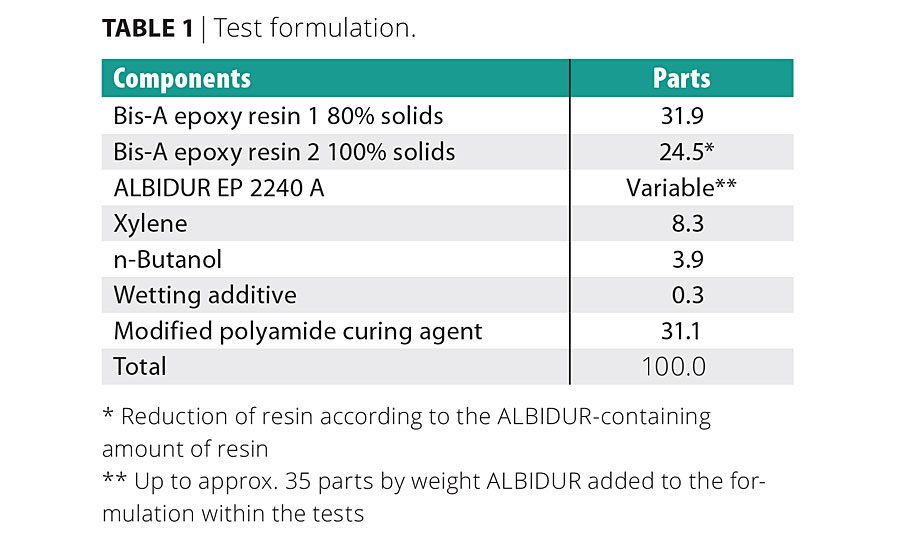

Test Formulations

A simple epoxy resin formulation consisting of two epoxy resins based on Bisphenol A were used as a base (Table 1). Further solvent was added to reduce the viscosity as well as a wetting additive to improve substrate wetting. To this was added an ALBIDUR product consisting of silicone elastomer particles (40%) and the Bisphenol A epoxy resin 2 (60%) used in the test formulation. The amount of epoxy resin 2 in the original formulation was reduced by the amount of epoxy resin 2 introduced by the ALBIDUR in the formulation. The ratio between the two epoxy resins and the solvents was thus held constant over the whole test series. Because no further solvent was added, the additional silicone elastomer particles in the formulation led to an increase in the solids content. The viscosity of the formulation increased significantly only above an ALBIDUR concentration of approximately 15% w/w (Figure 6). The coatings obtained were crosslinked stoichiometrically with a modified polyamide curing agent.

No pigments or fillers were added to the formulation so as to eliminate, as much as possible, side effects on the coating’s properties and the changes caused by the modification.

Specimen Preparation

The test coating was applied by knife on untreated steel panels resulting in a dry film thickness of approximately 60 µm. In contrast to spray application, knife application permits a uniform applied film thickness independent of the user. A ventilation time of approximately 10 min at room temperature was followed by drying and crosslinking in a circulating air oven for 30 min at 80 °C. To ensure that all specimens were completely cured, they were conditioned for a further 5 days at 60 °C before the mechanical tests were conducted.

Impact Strength Increased

Impact strength characteristics were investigated by the falling weight and stone chip tests. Significant improvements in properties were observed in both tests.

The Falling Weight Impact Test was carried out with a 1 kg weight, and the height of fall was determined above which cracks or spalling became visible in the coating. In this case, the weight fell on the uncoated back of the specimen thus imparting a “reverse impact”. A pronounced rise in the critical drop height, initially 10-15 cm, to 90 cm was observed with increasing silicone elastomer content without defects occurring (Figure 7).

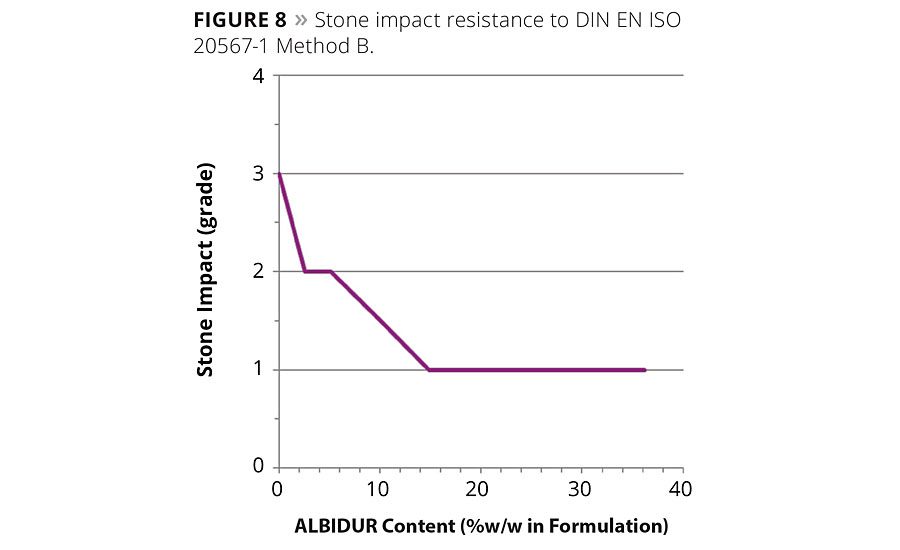

The Multi Impact Stone Chip Test also showed positive results when core-shell particles were used in the formulation. This was carried out using test procedure B, described in DIN EN ISO 20567-1, in which 500 g of chilled-iron grit was projected twice at a defined pressure for a specified time onto the coating. The characteristic value improved from 3 to 1 with higher core-shell content (Figure 8).

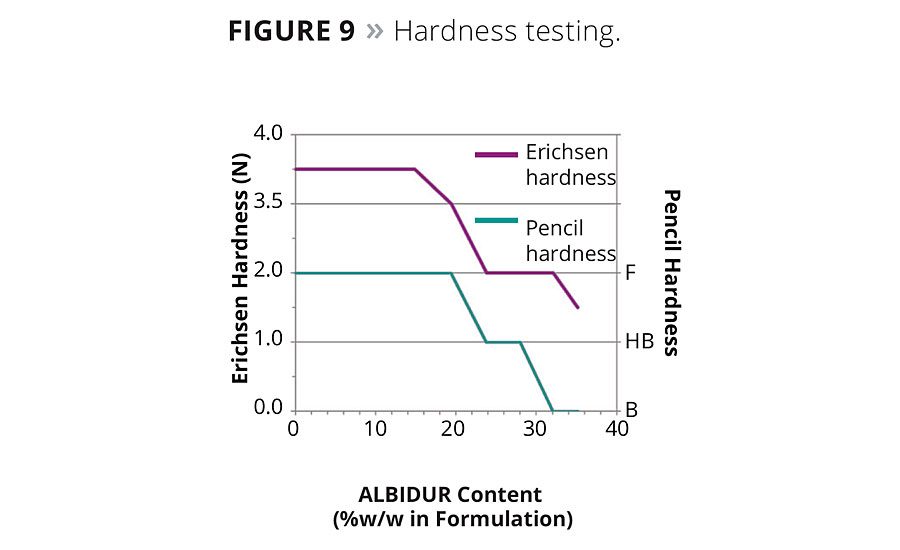

A reduction in hardness occurs only at very high concentrations of the silicone elastomer particles (Figure 9). At these higher concentrations, no further improvement could be detected in the impact strength, and the optimum was reached at approximately 15% w/w ALBIDUR (6% w/w elastomer particles) in the formulation. A significant increase in impact strength is possible without impairing hardness.

Improved Corrosion Resistance and Adhesion

The influence of the elastomer particles on other coating properties was investigated using further tests. Important, widely used methods for testing corrosion resistance are the Salt Spray Test (DIN EN ISO 9227) and the Constant Climate Condensation Water Test (CC test, DIN EN ISO 6270). In both tests, it became clear that coating modification with ALBIDUR products can provide improvements.

Using the CC test, the specimens were exposed for 240 h to a warm (40 °C) atmosphere saturated with water vapor. None of the specimens exhibited blisters, spalling or other perceptible optical defects. However, clear differences in adhesion on the various specimens could be detected using the cross-hatch test. After 240 h CC testing, adhesion improved with increasing ALBIDUR content (Figure 10).

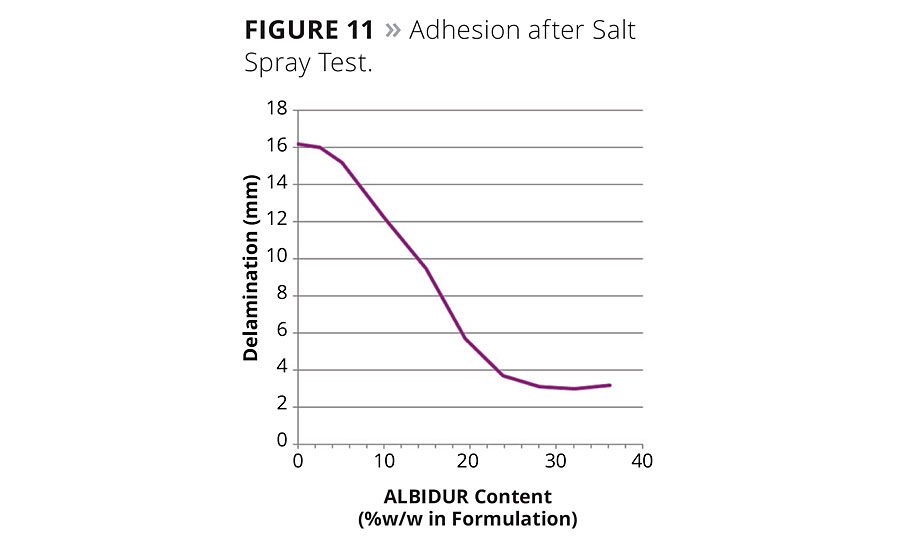

The Salt Spray Test, in which the specimens were subjected to a neutral salt spray mist for 168 h, was used to further evaluate corrosion resistance. It also became apparent that the use of silicone elastomer particles results in improvement. Detachment at the scribe was significantly reduced from initially 16 mm to under 4 mm with higher elastomer particle content (Figure 11).

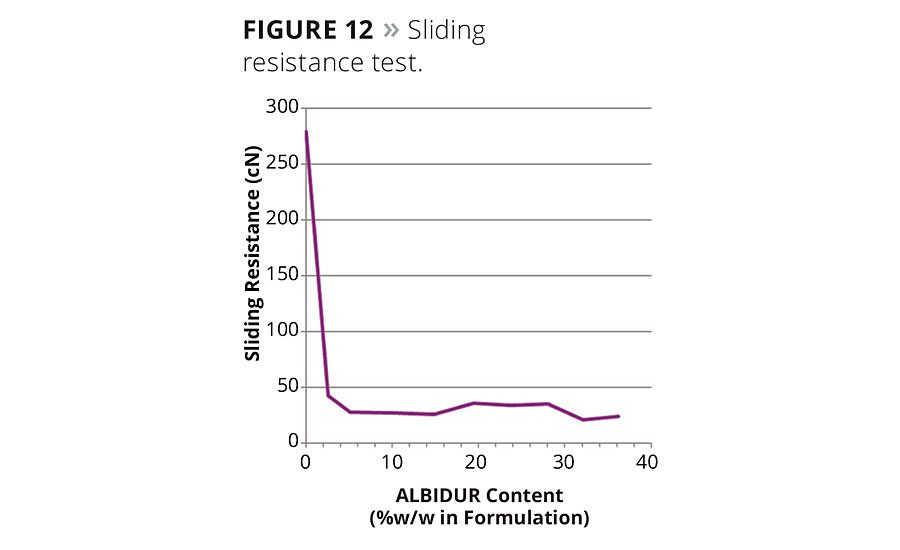

Reducing Friction

In addition to the aforementioned improvement in properties, slide resistance on the surfaces of the cured specimens was also reduced with increasing amounts of elastomer particles. The slide resistance was determined by measuring the force necessary to draw a weight of defined size and surface at a defined speed over and parallel to the coating surface. Even at low additions of elastomer particles, the resistance was markedly reduced. Thus, a reduction in slide resistance of about 85% from 279 cN to 43 cN was already apparent at an ALBIDUR content of only approximately 2.5% (Figure 12).

Summary and Outlook

The tests showed clearly that the coating properties investigated can be significantly improved by the use of ALBIDUR technology. Both the mechanical impact strength characteristics and resistance to atmospheric effects improve with increasing concentration of silicone elastomer particles. In the present test series, the optimal concentration of silicone elastomer particles in the formulation was about 15% w/w. At this concentration, significant improvements in impact strength were achieved without detectable impairment of the coating hardness. The impact resistance rose by approximately 900%, and stone chip resistance also exhibited an improvement of up to about 200%. Further increases in particle concentration do not result in further rise in impact strength properties (Figures 7-8). The results of the CC and Salt Spray Tests were comparable. Here too, significant improvements were achieved by the use of silicone elastomer particles. Adhesion after the CC test and the Salt Spray Test was markedly raised. Furthermore, a clear reduction in slide resistance was observed with the use of even very small amounts of elastomer particles. In addition to the increase in impact resistance, slide resistance is a further interesting property change stemming from ALBIDUR-technology, which could be used, for example, for coating the inner walls of pipelines.

Further investigations will examine the behavior of core-shell silicone elastomer particles in pigmented formulations and also focus on other changes in system properties such as performance at low and elevated temperatures. ALBIDUR technology in various resin systems is also available for use in pigmented stoving enamels, 2-pack PUR, UV-curable and 2-pack PUR waterborne coatings systems.

This article originally appeard in Farbe und Lack. For more information, contact fabian.eichenberger@evonik.com.

References

1 Chen, J.; Kinloch, A.J.; Sprenger, S.; Taylor, A.C. The mechanical properties and toughening mechanisms of an epoxy polymer modified with polysiloxane-based core-shell particles, Polymer2013, 54, 4276.

2 Heuer, M. Hard and Tough, RADTech Europe 2009.

3 Pyrlik, M.; Block, H. Polysiloxandispersion, Verfahren zu ihrer Herstellung und ihrer Verwendung, Pantent EP 0407834 A 2, 1989.

4 Nanoresins AG: Product portfolio ALBIDUR®, 2009.

5 Kinloch, A.; Taylor, A.; Mohamed, R.; Sprenger, S. Rubber-Toughening and Nanoparticles in Epoxies: Synergies in FRC, 2009.

6 Evonik Industries AG: TEGO Nanoresins – Perfekter Schutz für makellose Schönheiten, 2014.

By Fabian Eichenberger, Marco Heuer and Sascha Herrwerth, Ph.D. | Evonik Industries, Essen, Germany

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!