An Exclusive Look Inside DCM’s Lab

Dow Coating Materials (DCM) recently invited PCI’s Editors and Publisher to attend a private tour of its R&D labs in Midland, MI, to learn about products in development in the industrial coatings arena. Hosted by Chuck Martz, Global Business Director, Industrial Coatings, and Bob Mussell, R&D Director, Industrial and Functional Coatings, we were introduced to a world that not many in our industry have the privilege to experience. “We were thrilled to have a chance to give PCI Magazine a sneak peak at some of our new chemistries in the pipeline for industrial coatings, as well as new applications in the field,” said Martz.

First off was a unique process called BLUEWAVE™ technology. BLUEWAVE is Dow’s proprietary and patented mechanical-dispersion technology that was developed in Dow Chemical’s unique Core Research and Development organization. Core R&D was designed to provide leveraged research and development capabilities to all Dow businesses. The organization consists of about 1000 people across many different disciplines. All of Dow’s businesses can leverage this resource to develop technology and projects. “Even though we already have a large R&D organization within Dow Coating Materials, we can utilize the efforts of the Core R&D group to bring new technology in,” said Mussell.

BLUEWAVE technology is a perfect example of a tool developed in Core R&D that has allowed DCM to develop new products. This continuous and cost-effective process allows Dow researchers to disperse almost any polymer in water, resulting in a water-based dispersion with performance attributes on par with solvent-based polymers.

In the BLUEWAVE dispersion development lab, Dr. Jay Romick, Principal Research Scientist R&D, said, “The Holy Grail is to make a waterborne coating that gives the performance attributes of a solventborne system. BLUEWAVE gives us an advantage over other technologies to actually create waterborne solutions that provide us with performance attributes that are very, very reminiscent of a solventborne system.” Other forms of mechanical dispersion require modification of the polymer in order to disperse it in water, resulting in higher cost and decreased properties of the base resin due to the introduction of water sensitivity. The BLUEWAVE process enables the production of a waterborne dispersion without modifying the resin. Because Dow has a massive array of polymers to work with, DCM’s researchers have the opportunity to tailor the performance attributes of the end dispersion by using one or more polymers to adjust overall performance properties.

Specific areas of development in DCM’s Bluewave Technology lab include polyolefin-based dispersions and alkyd dispersions. Solid pellets, dispersants and surfactants are poured into an extruder designed and patented by Dow engineers. What comes out the other end is a waterborne dispersion. “From a formulator’s standpoint, the resulting emulsion is going to act very much like any other emulsion, but the property balance will differ depending upon the polymer mix used. For example, polyolefins are very hydrophobic, chemically resistant, and in contrast to other polymer systems like epoxies, coatings made with these are very, very durable in terms of flexibility and impact resistance,” said Romick.

In the alkyd technology arena, Dow is in the process of developing waterborne alkyd dispersions with equivalent or better performance than traditional solventborne systems. The normal approach to making low-VOC waterborne alkyd dispersions can be very challenging, if not impossible, because the viscosity of the resin may be too high to make a dispersion without the addition of significant amounts of solvent. Dow is able to heat the alkyd and perform a direct emulsification with the BLUEWAVE process, delivering alkyd dispersions with up to 60% solids and very low viscosity.

High-Throughput Labs

Another powerful resource available to all Dow businesses is high-throughput (HTP) technology. There are about 20 HTP labs on the Dow campus in Midland. HTP tools allow researchers to take information obtained in Core R&D a step further to develop new products. Researchers can follow products from formulation through application testing in a modular approach. Each formula is assigned a bar code, which is scanned each time it enters a new area of the HTP testing lab. All of the information for that particular bar code, including the formulation information and all of the testing data, is stored and analyzed. HTP is fast and continuous, and enables DCM to accelerate research.

Acrylic Coatings for Metal

While in the HTP lab, Dr. Leo Procopio, Technical Service Group Leader, discussed acrylic coatings for metal. Within the last 10 years, the company has introduced its AVANSE™ technology, which has provided a step change in how acrylics perform on metal substrates – particularly with corrosion resistance. With AVANSE, the latex particles adsorb onto the pigment surface. In the industrial space this results in better pigment spacing, which improves hiding and barrier properties, and allows for its use in medium-duty applications. Formulators are able to achieve very high performance with a one-component waterborne coating at VOC levels of 100 g/L and below.

In step with green building trends in commercial and institutional architecture, DCM recently introduced two new resin technologies for low- and ultralow-VOC coatings. MAINCOTE™ 4950 acrylic resin facilitates formulation of direct-to-metal (DTM) coatings with high performance at VOC levels of 50 g/L or less. Compared to current DTM finish coats formulated at various VOC levels, MAINCOTE 4950 offers an improved balance of hardness, corrosion and durability properties, as well as good architectural gloss and trim paint properties.

“The breadth of coatings applications in commercial architecture spans a wide range of regulatory requirements,” said Mary Rose Correa, North American Industrial Coatings Field Marketing Manager. “The broad utility of MAINCOTE 4950 allows us to offer a single resin solution that meets this wide range of requirements without sacrificing sustainability or performance.”

DCM also recently launched MAINCOTE AEH acrylic epoxy hybrid, which combines the weatherability and UV resistance of acrylics with the chemical resistance of epoxies for two-component (2K) concrete coatings. This resin offers excellent tire pickup resistance in waterborne 2K concrete coatings, making it an excellent choice for commercial flooring and residential garage floors where high performance and ultralow VOC is desired. For commercial and institutional wall applications, the product offers excellent resistance to aggressive cleaning regimens while contributing to improved aesthetics in daylighted interiors. “The use of natural lighting is a growing trend in green building that reduces the cost and carbon footprint associated with artificial lighting,” said Procopio. “In addition to lowering VOC to ultralow levels, MAINCOTE AEH adds the UV resistance that’s needed to fight the yellowing that can occur in daylighted interiors.”

Functional Coatings

Procopio’s group is also doing a lot of work with functional coatings. Thermal insulation coatings, based on MAINCOTE IC acrylic resins, lower the surface temperature of pipes and tanks. Unlike traditional insulation methods that allow water to seep beneath them, thermal insulation coatings form a seal with the substrate, preventing corrosion. This product can be used for safe-touch coatings and insulating tanks, and is an easy way to insulate complex geometries. Companies are also looking at the coating for energy management, as it can reduce the frequency and duration of tank heat-up.

Another functional coating recently developed is -ACOUSTICRYL™ sound-damping technology. ACOUSTICRYL helps reduce noise resulting from vibration, and is an excellent replacement of bitumen pads in automobiles.

Products Under Development

The tour also included a look at several products under development in areas such as construction equipment, protective coatings, wood applications and automotive refinishing.

One such technology is the development of polyurethane coatings without using isocyanates. Kristine Poblete, Global Metal Lead/Strategic Marketing NAA, noted, “One of the key challenges in industrial coating applications, particularly for those using solventborne polyurethanes, is the problem of choosing between a long pot life or a fast cure time – there is always a tradeoff. This new chemistry decouples pot life from cure time, so you can have a long pot life and a very short cure time.” Another benefit to this ISO-free technology is that it cures at ambient temperature.

Standing in front of an automotive refinishing spray booth, Paul Popa, Senior Research Scientist, DCM R&D, described several performance attributes of this technology, including less waste due to longer pot life, faster throughput due to faster dry times and less energy consumption due to ambient curing. The technology, which is manufactured without isocyanate, features both acrylic-based and alkyd-based versions designed for exterior maintenance and protective applications, industrial wood applications, and automotive refinish applications.

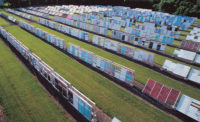

Another area under development in the Dow laboratory involves can coatings. Today, epoxy is widely used for the over 300 billion cans that are coated globally every year. Tapping into its BLUEWAVE technology and employing a lab-scale system that replicates the process used by commercial-scale can coaters, DCM is developing a BPA-free coating alternative for both food and beverage cans.

When developing these and other new polymer technologies for industrial coatings, Dow researchers immerse themselves in both the formulator and end-user experience. “In order to provide the best solutions, we need to understand the formulation space as well as customers and, where new chemistries are involved, we need to be able to provide our customers with robust technical support so that their reformulation process runs smoothly and seamlessly,” said Martz.

Jonathan Mason, Associate Research Director, added, “We’re not just designing polymers. We’re becoming experts in how the polymer is formulated by our customers to make a coating. We’re also becoming experts in how this new polymer works at the can makers who apply the coating. And we’re even working with brand owners to understand their requirements in terms of performance of sensory or safety aspects. So it’s not just ‘invent the polymer and then see what happens.’ It’s really an integrated R&D cycle that allows us to supply the best products to our customers.”

PCI would like to thank all of those representing Dow Coating Materials for taking the time to show us around the Dow facility and explain these new technologies. We look forward to publishing several articles later this year on some of these new products.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!