Aerogel Insulative Coatings

New Coating Technology Offers Personnel Protection

According to the American Burn Association, there are approximately 4,000 hospitalizations due to occupational contact burn injuries each year,1 and likely many unreported incidents. Lost time and productivity, medical costs, litigation expenses and other factors related to these injuries account for millions in lost profits and, more importantly, the immeasurable cost of mental and physical pain endured by the victims. Industrial facilities all over the world house hot, uninsulated pipes, vessels and other equipment – all hazards with the potential to cause employees debilitating contact burn injuries. While it is the aim of most organizations to maintain a workplace safe for employees, solutions are often difficult or costly to implement.

ASTM standards C1055 and C1057 provide process engineers and system specifiers detailed analytical methods to determine how to make their processes safe from burn hazards and determine acceptable heated surface conditions in the workplace.2,3 These OSHA-endorsed4 standards also describe the use of instrumentation to measure the level of safety provided by installed systems.

Until recently, when a heated system required modification for personnel protection, the choices were conventional insulation, such as fiberglass or mineral wool, physical barriers, or administrative controls (HazCom signage). While applying conventional or fibrous insulation is sufficient to reduce the burn hazard, it can increase risk of corrosion under insulation (CUI), and be difficult and costly to install, particularly if a system is very large, in service or of a complex design.

Recent developments in insulative coating technology are a breakthrough for heated systems operators searching for burn protection solutions. Even a thin layer can meet surface safety requirements. Coatings can be sprayed on using traditional methods, making application less costly than mechanical insulation, with a finished product that is highly durable and resists corrosion.

The differentiating factor among currently available insulative coatings is the type of insulation additive used. Traditionally, the primary insulation has been hollow ceramic microspheres, which provide improved thermal performance due to their hollow structure. Recently, formulators have begun to use aerogel particles as the key additive in insulative coatings. Aerogel, a class of highly porous solid materials known for its outstanding thermal insulation properties, is made using amorphous silica as the base structure. The fine pore structure results in a thermal conductivity of approximately 0.012 W/m-K (.007 Btu-ft/[h-ft2 °F]), compared to ceramic microspheres at 0.05 to 0.2 W/m-K (.029 to .116 Btu-ft/[h-ft2-°F]). Unlike hollow microspheres, which degrade when ruptured, aerogel particles can be broken down in processing without losing their insulating properties.

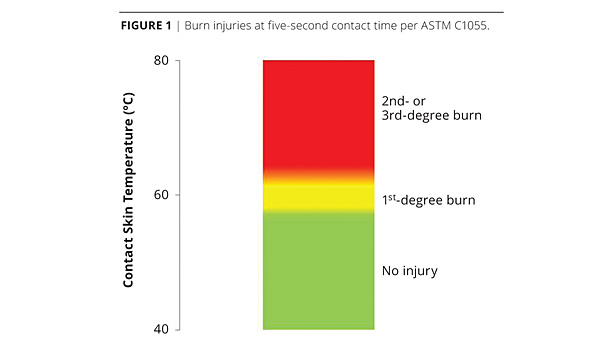

Burn Hazard Guidelines and the Thermesthesiometer

ASTM C1055 outlines what constitutes a reversible or irreversible skin injury, making recommendations for time-temperature thresholds for industrial and consumer products. In industrial settings, a five-second contact time would cause pain at temperatures between 44 °C (111 °F) and 48 °C (118 °F). The onset of a first degree burn would be reached at 58 °C (137 °F), and a second degree burn would occur at 61 °C (141 °F) or above (Figure 1).5,6

ASTM C1057 highlights the tools, such as the thermesthesiometer, used to determine if a burn will result under surface conditions. Specifically, the standard outlines how to calculate, or measure, contact skin temperature (Tc), defined as the temperature at the interface of the epidermis and dermis layer of the skin – approximately 80 to 100 microns below the surface of the skin.

The thermesthesiometer comprises a thermocouple embedded in a temperature-controlled silicone ‘finger,’ and directly measures the temperature at this point, 100 microns below the surface of the silicone ‘tissue.’ This measurement closely approximates the actual contact skin temperature for an existing heated system.7

Evaluation of Insulative Coatings

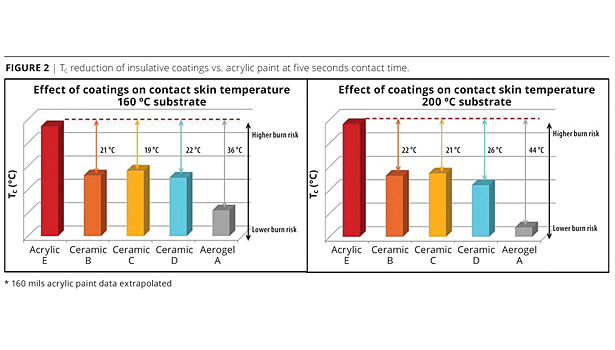

Using the thermesthesiometer, four commercially available coatings containing either ceramic or aerogel insulation were evaluated against an acrylic baseline for Tc at five seconds. Figure 2 shows the performance of the 40-mils-thick coatings at substrate temperatures of 160 °C and 200 °C.

At both substrate temperatures, the aerogel coating A shows superior performance. Compared to ceramic coatings, aerogel coating A reduces Tc by more than 14 °C at 160 °C substrate temperature and by more than 18 °C at 200 °C.

When it comes to personnel protection, a differential of as little as 3 °C (5 °F) in Tc at five seconds can mean the difference between no burn and an OSHA-recordable injury (see Figure 1), which means aerogel insulative coatings provide a significant added margin of safety over ceramic coatings.

Safety Beyond Burn Protection

Personnel protection in an industrial workplace goes beyond just burn prevention. The ASTM standard notes onset of a first degree burn as the upper limit of injury for a hot surface contact event. However, an employee unexpectedly coming into contact with such a surface would likely experience immediate discomfort and pull away from the surface. This reflex reaction can cause a variety of safety issues, particularly if the work is being done in close or crowded working quarters. Just a few millimeters of an aerogel insulative coating can mitigate this sequence of events by keeping the skin contact temperature not only below the irreversible skin injury threshold, but also near or below the pain threshold.

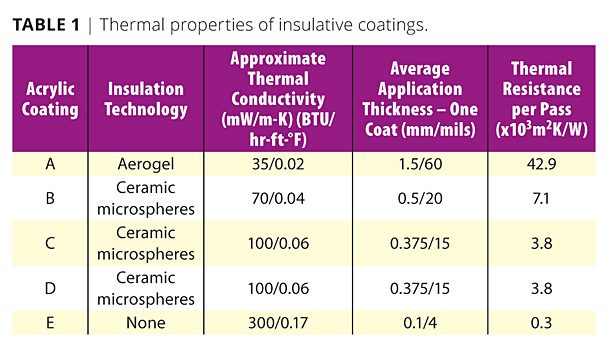

Fewer Coats Means Improved Economics

Unlike typical coatings, both ceramic beads and aerogel particles allow for a thicker application per coat. Ceramic microsphere-enabled coatings can be applied at 15-20 mils (0.37 -0.5 mm), and aerogel-enabled coatings can be applied at 60 mils (1.5 mm) or greater per coat. See Table 1 for typical properties of all the coatings tested.

Insulative coating thickness is specified based on the thermal resistance required for the application. In Table 1, a comparison of thermal resistance of the different coatings shows that the aerogel coating has a thermal resistance per pass (R-value per coat) of six to 11 times the ceramic microsphere coatings. This means six to 11 coats of the ceramic coating are required to match the thermal performance of one coat of aerogel-enabled coating A. To achieve a safe touch surface condition at substrate temperatures tested, ceramic coatings require multiple passes, resulting in dramatically increased cost due to extended installation time, facility down time and delayed installation of other equipment. In contrast, aerogel insulative coatings provide improved burn protection for all applications up to 200 °C (392 °F) in a single pass.

Aerogel Coatings: The Future of Personnel Protection

Hot surfaces are present in nearly every industrial and commercial property today, and in order to comply with OSHA regulations and internal safety guidelines, facility operators must protect employees from exposure to these hazards. Aerogel additives, such as Cabot’s Enova® aerogel, allow formulators to create next-generation protective coatings for applications where personnel require protection from hot surface contact. Easier and more cost effective to apply, testing shows that aerogel insulative coatings provide a dramatic improvement in burn protection over other commercially available options – making them a groundbreaking opportunity for facility operators seeking to address personnel protection.

References

- American Burn Association 2012 Burn Incidence Fact Sheet, http://www.ameriburn.org/resources_factsheet.php.

- ASTM Standard C1055 (2009), Standard Guide for Heated System Surface Conditions that Produce Contact Burn Injuries, ASTM International, West Conshohocken, PA.

- ASTM Standard C1057 (2010), Standard Practice for Determination of Skin Contact Temperature from Heated Surfaces Using Mathematical Model and Thermesthesiometer, ASTM International, West Conshohocken, PA.

- Occupational Safety and Health Standards Interpretation Letter, Aug 19, 1998, http://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=INTERPRETATIONS&p_id=22617.

- Moritz, A.R.; Henriques, F.C. Studies of Thermal Injury Part II. The Relative Importance of Time and Surface Temperature in the Causation of Cutaneous Burns, American Journal of Pathology1947, 23, 695-720.

- Wu, Y.C. Control of Thermal Impact for Thermal Safety, AIAA Journal1977, 15 No 5, 674.

- Marzetta, L.A. Engineering and Construction Manual for an Instrument to Make Burn Hazard Measurements, Feb 1974, NFS TN-S16, National Bureau of Standards, Washington, D. C.

Looking for a reprint of this article?

From high-res PDFs to custom plaques, order your copy today!